The Evolution of Gold Refining Technology: How Modern Equipment Has Changed the Industry

For thousands of years, humans have been fascinated by gold. Not just for its beauty, but for its enduring value and utility. The process of gold refining dates back to ancient civilizations like Egypt, Mesopotamia, and the Indus Valley, who pioneered early methods to extract and purify gold from raw materials. Over time, gold refining has evolved from basic fire-based techniques to advanced chemical and electrochemical processes that achieve exceptional levels of purity.

In today’s world, gold refining plays a critical role in global industries such as electronics, jewelry, and finance, and in environmental sustainability. Modern refiners focus on reducing toxic byproducts, reclaiming precious metals from waste, and implementing eco-friendly technologies to ensure cleaner, safer refining practices.

This blog explores the evolution of gold refining, from ancient methods to today’s advanced, eco-friendly technologies, and how each era shaped the innovations we use today.

Looking for the best precious metal refinery?

3,000 BCE – 500 BCE: The Beginnings of Gold Refining

The ancient civilizations of Egypt, Mesopotamia, and the Indus Valley pioneered early gold refining techniques. They were the first to use clay pipes and furnaces in smelting and employed placer mining to extract gold from riverbanks, collecting particles found in sand. Through the use of fire and basic tools, they began separating impurities from gold, marking the birth of gold refining. These cultures were revolutionizing the process by using heat to extract gold from stone and rock, a groundbreaking advancement in early metallurgy.

Notable techniques included:

- Cupellation: A fire-assay method where a mixture of metals is heated in a porous container, allowing base metals to oxidize and separate, leaving behind purified precious metals.

- Cementation: A process that uses a reducing agent, like salt, and heat to isolate and concentrate gold from ore.

Drawbacks: Cupellation was labor-intensive and required precise temperature control, something difficult to maintain without modern equipment.

500 BCE – 500 CE: The Greek and Roman Advancements

The Greeks and Romans advanced gold refining by merging alchemy with early scientific principles. They introduced mercury amalgamation, mixing gold with mercury, then heating it to evaporate the mercury and leave behind gold. This technique laid the groundwork for modern chemical gold refining.

- Mercury Amalgamation: Enabled the extraction of gold from ore but posed significant health and environmental risks.

- Acid Refining: Early methods of dissolving base metals with acids helped evolve today’s chemical gold refining processes.

Modern Mitigation: Today, dental offices use amalgam separators to reduce mercury discharge into sewer systems, and many recycling companies specialize in mercury-safe disposal.

500 CE – 1500 CE: The Medieval and Renaissance Shift

Gold refining declined during the early medieval period but saw renewed interest during the Renaissance. The focus shifted toward assaying, the practice of testing gold purity, which remains essential in modern gold refining.

Key techniques included:

- Touchstone Testing: Rubbing gold on a smooth, dark stone and comparing the streak to known samples to determine purity.

- Inquartation: Adding silver to a gold alloy to dilute it, making impurities easier to dissolve in acid and resulting in purer gold.

500 CE – 1500 CE: The Medieval and Renaissance Shift

Gold refining declined during the early medieval period but saw renewed interest during the Renaissance. The focus shifted toward assaying, the practice of testing gold purity, which remains essential in modern gold refining.

Key techniques included:

- Touchstone Testing: Rubbing gold on a smooth, dark stone and comparing the streak to known samples to determine purity.

- Inquartation: Adding silver to a gold alloy to dilute it, making impurities easier to dissolve in acid and resulting in purer gold.

The Industrial Revolution (18th–19th Century)

The demand for standardization and industrial efficiency revolutionized gold refining. Two landmark techniques emerged:

- Miller Process (1867): Invented by Francis Bowyer Miller, this method uses chlorine gas to react with impurities in molten gold, forming a removable slag. Ideal for refining large quantities quickly.

- Wohlwill Process (1874): Developed by Emile Wohlwill, this electrolytic method uses an electric current to dissolve impure gold, leaving pure gold to collect on a cathode. It achieves up to 99.999% purity.

These innovations transformed industries such as jewelry, electronics, and currency production, and laid the foundation for modern gold refining practices by enabling the production of pure gold in large quantities.

20th Century – Present: The Modern Era

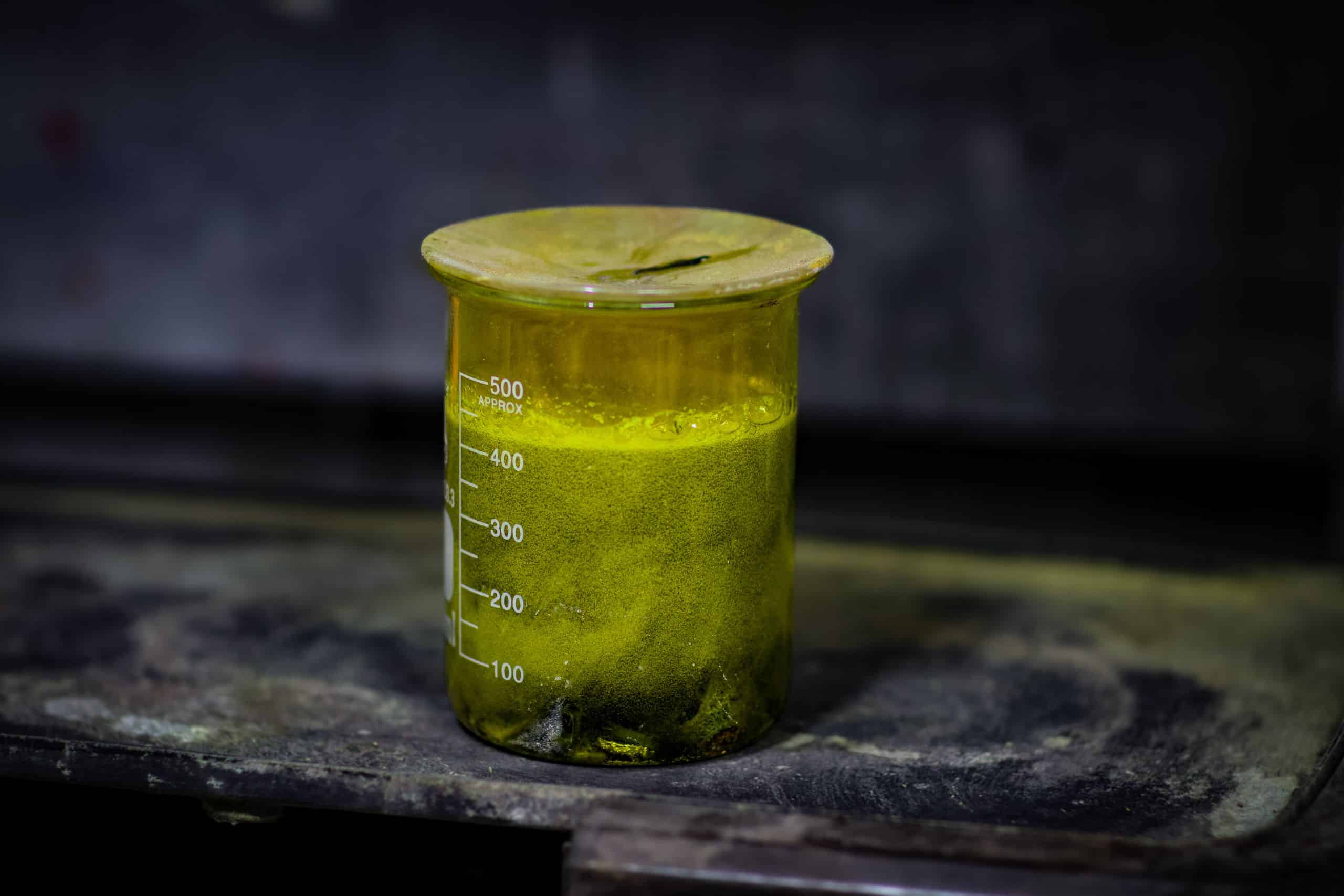

Modern gold refining has evolved into a high-tech industry prioritizing precision, efficiency, and environmental responsibility. Today’s methods include smelting, electrolysis, and aqua regia refining, which uses a powerful mix of nitric and hydrochloric acid to dissolve metals.

Recent advancements include:

XRF and ICP Spectrometry:

- X-ray Fluorescence (XRF): Measures emitted X-rays when a material is exposed to high-energy X-rays, identifying its elemental makeup.

- Inductively Coupled Plasma (ICP): Ionizes samples to detect trace elements with high accuracy.

Eco-Friendly Refining: Some refiners now recycle scrap gold and use bio-based solvents and renewable energy sources, reducing reliance on toxic chemicals and minimizing environmental impact in the gold refining industry.

20th Century – Present: The Modern Era

Modern gold refining has evolved into a high-tech industry prioritizing precision, efficiency, and environmental responsibility. Today’s methods include smelting, electrolysis, and aqua regia refining, which uses a powerful mix of nitric and hydrochloric acid to dissolve metals.

Recent advancements include:

XRF and ICP Spectrometry:

- X-ray Fluorescence (XRF): Measures emitted X-rays when a material is exposed to high-energy X-rays, identifying its elemental makeup.

- Inductively Coupled Plasma (ICP): Ionizes samples to detect trace elements with high accuracy.

Eco-Friendly Refining: Some refiners now recycle scrap gold and use bio-based solvents and renewable energy sources, reducing reliance on toxic chemicals and minimizing environmental impact in the gold refining industry.

Refining Gold, Refining Progress

From the fire-driven furnaces of ancient civilizations to today’s precise, environmentally responsible methods, the evolution of gold refining reflects humanity’s ongoing quest for innovation, purity, and sustainability. Each era introduced key advancements that shaped how we recover and process gold, transforming industries and setting new standards along the way.

As environmental concerns become increasingly important, modern gold refining practices continue to adapt, with technologies designed to reduce waste, recover precious materials more efficiently, and minimize harm to our planet.

To learn more about how today’s gold refineries are working to reduce their environmental footprint, check out our related article: How Gold Refineries Decrease the Carbon Footprint.

At Core Scientific, we utilize state-of-the-art gold refining technology to ensure premium recovery from scrap gold, maximizing returns for our customers. We’re committed to sustainability and transparency, placing environmental responsibility at the forefront of our refining practices. Find out how we can help you, schedule a free consultation today!